You’ve made a beautiful 3D scan, sharp, detailed, and full of potential. But once you’ve captured the perfect model, what’s next? Whether you’re creating a custom orthotic, designing an animation, or preparing a CAD-ready prototype, you’ll need the right 3D scanning software to process your scan.

At Structure, we know that turning a scan into something usable requires a powerful secondary tool. iPads and mobile devices are great for capture, but 3D mesh cleanup, analysis, and editing are best done on a desktop computer with specialized software. This guide covers the software we use (and recommend) for different goals, from gaming and animation to scientific measurement and orthotic design.

General Purpose 3D Scan Processing Software

These programs aren’t built for any single industry, but they’re powerful, flexible, and widely supported. Whether you’re working in animation, research, or manufacturing, these are the most popular tools for post-processing your scans.

Blender — Ideal for Animation and Gaming

Pros: Free, widely supported, huge library of tutorials and plugins

Cons: Not optimized for CAD or precise measurements

Blender is one of the most popular 3D modeling and animation programs in the world, and for good reason. With over 30 years of development, a massive community, and thousands of free tutorials, it’s the go-to software for 3D artists and game developers. Even major studios use Blender for animation and design. In fact, 2024’s Best Animated Feature Flow was created entirely in Blender.

However, Blender’s strength in artistic modeling comes at a tradeoff. It’s not ideal for scientific or medical accuracy, since it doesn’t natively produce CAD files or offer precise, repeatable measurements. Plugins exist to fill these gaps, but documentation is limited and results vary.

At Structure, we use Blender on the CX side of our business. It’s perfect for quick visual inspections, mesh cleanup, and reformatting files. But for applications requiring scientific accuracy such as orthotics or medical analysis, we turn to more specialized tools.

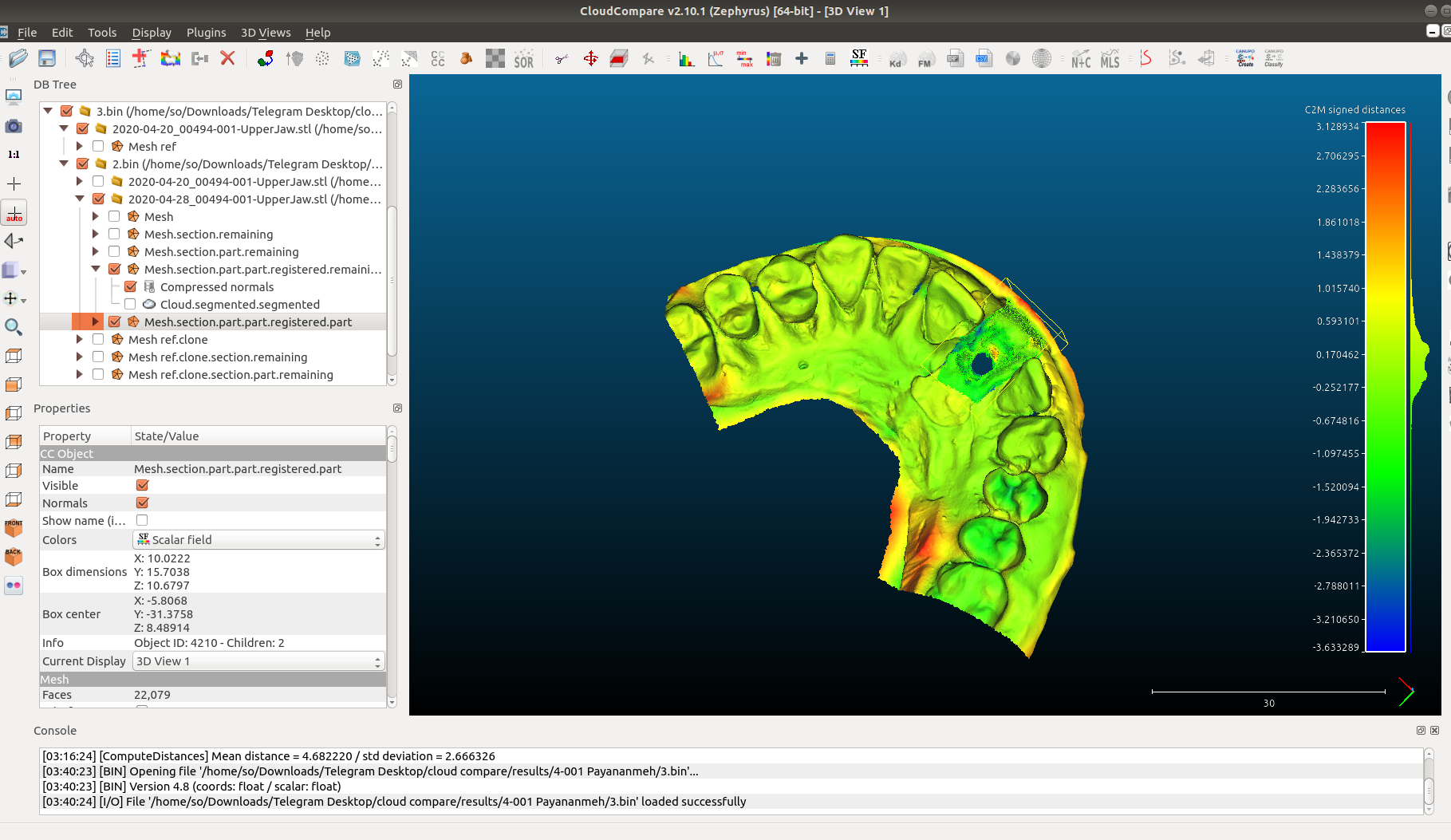

CloudCompare — Best for Measurement and Mesh Analysis

Pros: Free, advanced measurement tools, excellent for research

Cons: Steeper learning curve, not for CAD file creation

Ask a game designer about mesh processing and they’ll say Blender. Ask an engineer or researcher and they’ll say CloudCompare. Built by scientists for scientists, CloudCompare offers precision tools for measurement, alignment, and mesh analysis that you’d struggle to find elsewhere.

The program makes it easy to take repeatable measurements and compare 3D models with extreme accuracy. The mesh always stays centered, making it simple to orient and manipulate while ensuring consistent data points.

At Structure, we use CloudCompare for landmark detection accuracy testing, mesh validation, and scientific study preparation. It’s also our top recommendation for verifying the precision of a scan before 3D printing. While it’s less intuitive than Blender, CloudCompare is one of the most reliable open-source tools for engineering-grade results.

MeshLab — Best for Large Mesh Processing

Pros: Free, open source, handles large meshes efficiently

Cons: Less documentation and tutorials compared to Blender

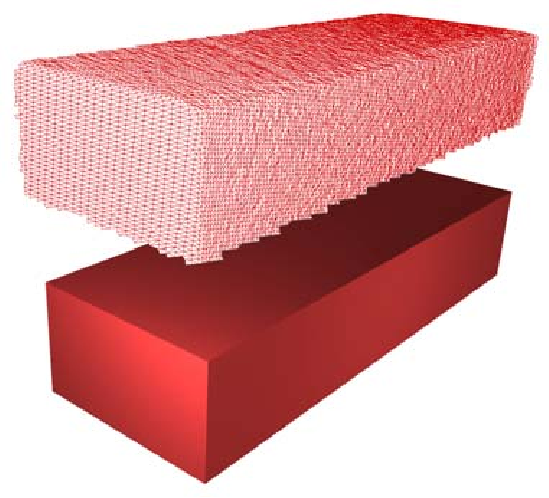

MeshLab is a robust, open-source tool designed to handle large 3D meshes with hundreds of thousands of vertices. It’s ideal for cleaning, repairing, and simplifying massive scan files. MeshLab supports scripts for custom workflows, allowing advanced users to automate repetitive steps.

It’s available across platforms such as Windows, macOS, iOS, and even as a web implementation in JavaScript, making it one of the most versatile 3D processing solutions available. However, because its community is smaller and its interface less polished, beginners may find it harder to learn.

If you’re managing large, detailed scans from a Structure Sensor 3 or similar device, MeshLab is a powerful and completely free choice.

AutoCAD — Industry Gold Standard for CAD Design

Pros: Professional-grade precision, solid modeling, excellent support

Cons: Expensive, limited mesh manipulation

AutoCAD is one of the oldest and most respected tools in digital design. It’s the industry benchmark for creating CAD models, blueprints, and schematics used across architecture, manufacturing, and product design.

However, 3D scanners, including the Structure Sensor 3, produce meshes rather than solids. That means files need to be converted before they can be fully manipulated in AutoCAD. Once converted, though, AutoCAD provides mathematical precision unmatched by mesh-based tools.

For workflows that demand exact geometry, such as manufacturing, tooling, or medical device design, AutoCAD remains a cornerstone software solution.

Specialized Software for Orthotics and Prosthetics (O&P)

For professionals in orthotics, prosthetics, and medical design, industry-specific 3D software streamlines the entire process from patient scan to final orthotic. These tools integrate clinical workflows, AI-based corrections, and direct manufacturing output.

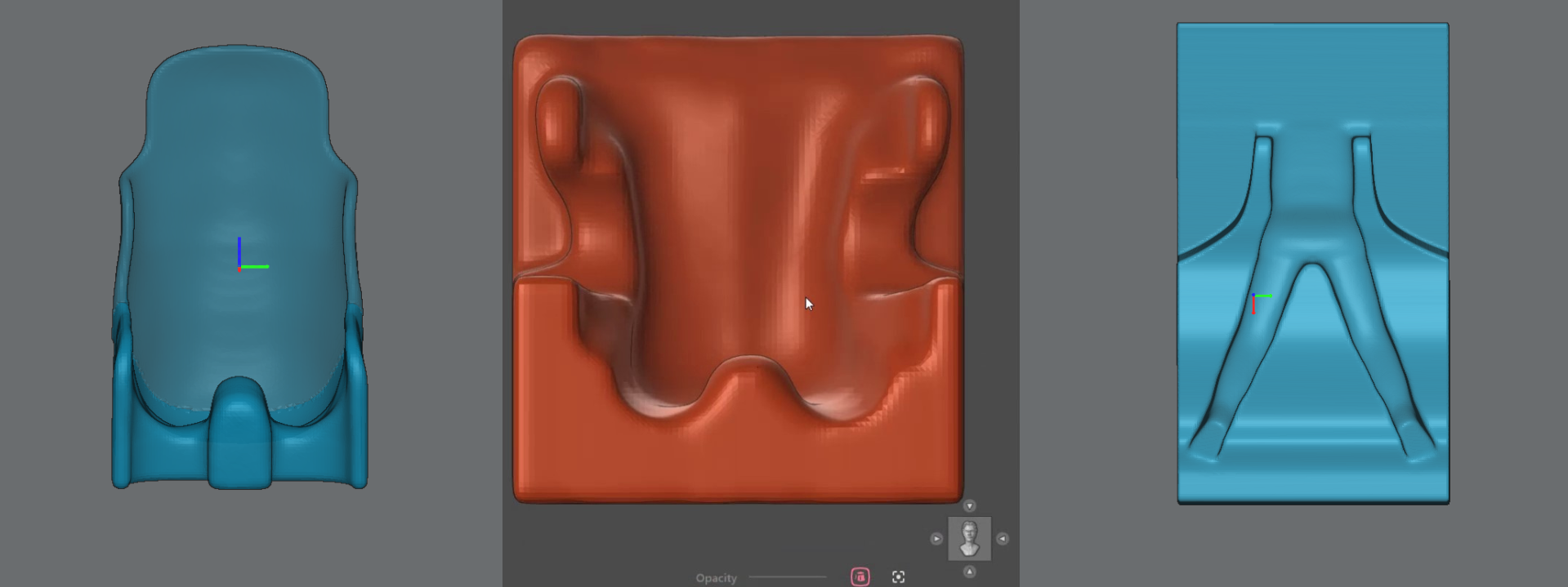

Qwadra — Cube Platform for Scan-to-Print Orthotics

Highlighted Solution: Cube

Qwadra is a leader in orthotic design and manufacturing solutions, offering scanners, printers, and workflow software for clinicians. Their Cube platform provides an all-in-one environment for processing patient scans, scaling, cleanup, and deformation to produce accurate, ready-to-print 3D models.

Cube’s streamlined design tools make it easy to generate high-quality orthotics or prosthetic models quickly, minimizing manual adjustments and improving production consistency.

Learn more about Qwadra’s Cube solution here.

Taika 3D Oy — TaikaCreate for Automated Custom Design

Highlighted Solution: TaikaCreate

TaikaCreate is an AI-powered orthotic design platform that automates the creation of custom foot and ankle devices. It processes 3D scans alongside clinician prescriptions, automatically generating optimized orthotic designs ready for CNC machining or 3D printing.

Technicians using TaikaCreate can generate up to 100 custom designs per hour without sacrificing accuracy or fit. The result is faster turnaround times, lower costs, and improved patient outcomes. With TaikaCreate, manufacturers can deliver clinically precise, scalable orthotic solutions across the globe.

Explore TaikaCreate’s capabilities here.

Toolkit3D — Build Your Own Scan-to-Fit Workflow

Highlighted Solution: Scan-to-Fit Design Engine

Toolkit3D takes a modular, cloud-based approach to orthotic design. Using their Scan-to-Fit Design Engine, you can create customized workflows tailored to your clinic or lab’s needs. From 3D scan import to final printable file, Toolkit3D’s flexible platform allows teams to build, test, and deploy new workflows quickly, all from any device, anywhere.

Learn more about Toolkit3D’s solutions here.

Conclusion

No matter your end goal, from orthotic manufacturing to 3D animation, having the right software for processing 3D scans is crucial. Whether you choose Blender for creativity, CloudCompare for precision, MeshLab for heavy meshes, or AutoCAD for solid modeling, each tool has unique strengths that complement your workflow.

For professionals in orthotics and prosthetics, specialized platforms like Qwadra Cube, TaikaCreate, and Toolkit3D deliver powerful, industry-specific solutions to streamline design and production.

At Structure, we stand behind every one of these tools, each tested, trusted, and compatible with the Structure Sensor 3, the most portable and affordable 3D scanning solution for professionals worldwide.